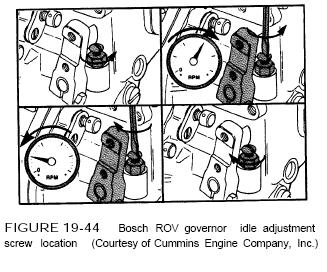

The idle adjustment screw location will vary based on the type of governor being used.

Once the engine is started, adjust the idle speed on industrial engines using an RSV governor by loosening the locknut and turning the screw (I), shown in Figure 19-43. CW rotation will increase the idle speed, and CCW rotation will decrease the idle speed. On automotive engines equipped with an RQV governor, refer to Figure 19-44 and using a 10-mm wrench and screw driver, rotate the screw CCW to raise the engine speed and CW to decrease the idle speed.

1. Start and run the engine at its idle speed. Use a tach and note the idle rpm. Compare this with the spec stamped on the engine CPL plate.

2. If idle adjustment is required, loosen the lock nut and back out the bumper spring screw until there is no change in the idle speed.

3. Adjust the idle screw to obtain an idle speed approximately 20 to 30 rpm lower than that recommended and lock the retaining nut.

4. Slowly turn the bumper spring screw (2) shown in Figure 19-43 CW only enough to bring the desired idle rpm to a stable speed, then lock the retaining nut.

Dear Sir ,

International DTA360 engine was installed for genset 200 kva but it generates only 120 amp. ( about 80 KVA ) .Tell me how to increase its power to get more power from this engine . engine serial number : 362GM2U114232

Regards

Ghassan

Hi i have a bosch injector pump and its installed on a 4bta Cummins. This engine is installed on a boat.i noticed that the trottle trys to go back when i accelerates the trottle. Do you think that there is something wrong in the pump may be a spring that has lost its tenshion.Thanks in advance John

Reason for over flow….how to stop it….

I opened it inside that relief valve no ball and spring is there its just bonjo bolt.

Why its come out…how to stop it

140 kva dg set Cummins, with Bosch in line pump, engine speed increases on partial loads

,how to adjust pump