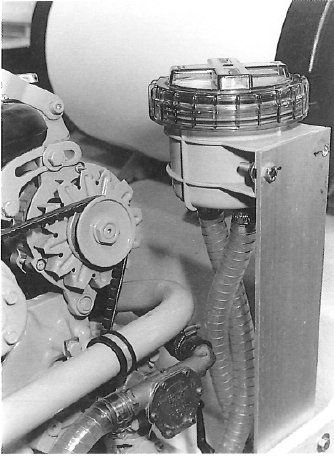

The water system should be plumbed using non-kink, large-bore water piping, long enough to soak up any engine movement, ideally double jubilee-clipped. The picture shows a Vetus strainer and Jabsco-type water pump.

Early pumps were generally reciprocating piston types, driven by an eccentric cam from the engine. They are rarely found on modern engines, most of which have rotary pumps with a rubber impeller.

Piston pumps

Grease piston pumps regularly via the greaser cup. It may occasionally be necessary to inspect the non-return valves.

Impeller pumps

These have a rubber bladed impeller (normally neoprene) rotating inside a round housing which has a depression machined between the inlet and outlet ports. The pump is driven directly by the engine. As the impeller rotates water is drawn in on the inlet side of the depression, and the blades carry it around until they reach the outlet side. Check valves are not required as the pumping action is continuous.

Neoprene impellers fitted to water pumps are reliable, unless run dry or allowed to become damaged by sand or debris. Use a dab of Vaseline to lubricate the replacement.

The effectiveness of the pump depends on the impeller fitting closely in the housing, which is why it tends to overheat and fail if allowed to run dry.

If the engine is laid up for a while, for example over the winter, the impeller should be removed and checked for damage before the engine is used again. Even if it looks good, but has had plenty of use, replace it anyway and always keep a service kit including an impeller and gasket on board.

The easiest way to remove an impeller is with a slip joint wrench (water pump pliers, preferably old ones with rounded teeth). Using screwdrivers is difficult and can damage the impeller, and the mating face of the pump.

Always apply light grease or petroleum jelly to both the impeller and the pump housing to enable it to run without problems until water starts passing through. Impellers impregnated with lubricant to withstand dry running for several minutes can be obtained.

A rubber seal behind the pump body stops water leaking out down the shaft, while a similar seal on the engine side stops oil leaking the other way. The gap between the two seals has a small drain hole. Should either water or oil be leaking from the hole the appropriate seal needs to be changed. If a water leak is left indefinitely a salt deposit will build up around the drain hole.