|

The ISX CM871 and ISM CM876 electronic control modules (ECM) are electronically operated fuel control systems that also provide many operator and vehicle features.

The base functions of the control system include fueling and timing control, limiting the engine speed operating range between the low and the high idle set points and reducing exhaust emissions while optimizing engine performance. The system also controls the engine brakes.

The control system uses inputs from the operator and its sensors to determine the fueling and timing required to operate at the desired engine speed at the required emissions level.

ECM Inputs

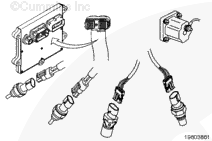

The ECM is the control center of the system. It processes all of the inputs and sends commands to the fuel system, vehicle and engine control devices.

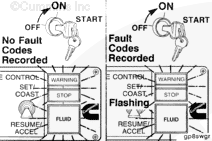

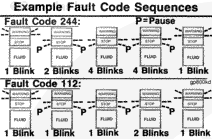

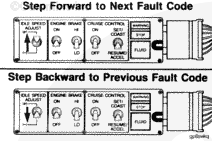

The ECM performs diagnostic tests on most of its circuits and will activate a fault code if a problem is detected in one of these circuits. Along with the fault code identifying the problem, a snapshot of engine operating parameters at the time of fault activation is also stored in memory.

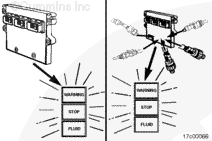

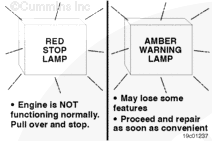

Active fault codes will cause a diagnostic lamp to activate to signal the driver.

The ECM can communicate with service tools and some other vehicle controllers (such as transmissions, ABS, ASR, electronic dash displays and so on) through the SAE J1939 data link.

Some vehicles and equipment will have SAE J1939 networks on them that link many of the “smart” controllers together. Vehicle control devices can temporarily command engine speed or torque to perform one of its functions (that is, transmission shifting, anti-lock braking and so on).

The control system utilizes a number of sensors to provide information on engine operating parameters. These sensors include:

- Engine coolant temperature sensor

- Intake manifold air temperature sensor

- Intake manifold pressure sensor

- Engine oil pressure sensor

- Engine speed (crankshaft position) sensor

- Camshaft position sensor

- Barometric pressure sensor

- Rail fuel pressure sensor

- Water-in-fuel sensor

- Turbocharger speed sensor

- Turbocharger compressor inlet air temperature sensor

- Accelerator pedal/lever position sensor

- Engine brake selector switches

- Engine coolant level sensor

- Vehicle speed sensors

- Feature control switches (i.e. cruise control switches)

- Fan control switch

- Air conditioner pressure switch

- Remote accelerator

- Remote PTO.

NOTE: These inputs are application dependent. Some applications will not use all of these inputs.

|

CAUTION

CAUTION

WARNING

WARNING