HEUI evolved from the EUI, and since mid-1994 has been used on Caterpillar, International T444E, DT466E, 1530E, certain Perkins models, and, most famously, on the Ford (International) Power Stroke. Unlike conventional camshaft-driven unit injectors, HEUIs are actuated by high-pressure crankcase oil. Since injection is no longer tied to camshaft motion, fuel can be injected at any crank angle. At higher-than-idle speeds, injector pressure is independent of engine rpm and can attain values of 30,000 psi.

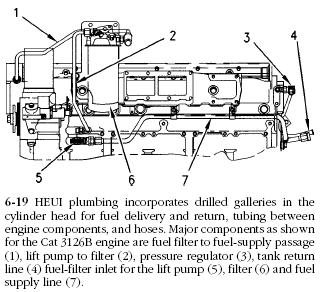

Figure 6-18 illustrates the general layout of the Cat system that differs only in detail from Ford and other HEUI applications. Figure 6-19 shows the arrangement of the piping for the 3126B truck engine, which is the focus of this discussion. The high-pressure oil pump delivers crankcase oil to the injectors at cranking pressures of 500 psi that increase to as much as 3300 psi under speed and load. The computer-controlled injector actuation pressure control valve (IAPCV) regulates oil pressure by shunting pump output to the crankcase. Fuel pressure is regulated to 55 psi minimum.

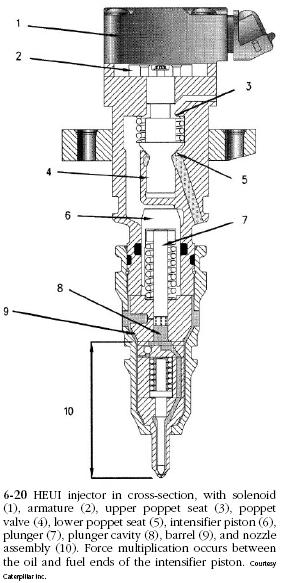

HEUI consists of five major components—a solenoid, poppet valve, mushroom shaped intensifier piston, barrel, and a seven-hole nozzle assembly (Fig. 6-20). Approximately 4A is required to energize the solenoid and 1.5A holds it open.

Upon command, the solenoid opens the poppet valve to admit high-pressure lube oil to the upper end of the intensifier piston (6 in Fig. 6-20). The oil forces the piston and plunger (7) down against fuel trapped in the injector body by a ball check valve. The fuel end of the plunger is smaller in diameter than the upper, or oil, end. The difference in cross-sectional area multiplies the hydraulic force acting on the fuel 7.5 times, to produce injection pressures of 3000–30,000 psi. Pressurized fuel lifts a second check valve, enters the cavity on the lower right of the drawing, and reacts against the needle shoulder to overcome spring tension. Nozzle-opening pressure (NOP) varies with the application. Some Cat injectors have an NOP of 4500 psi. Rebuilders of Power Stroke HEUIs look for 2750 +/_ 75 psi.

Note that both band width (the time the injector is open) and actuator-oil pressure determine the amount of fuel delivery.

HEUI injectors have undergone constant refinement. The most significant change is the split-shot PRIME (preinjection metering) version that first appeared on 1994 California Ford F series trucks and has since become almost universal.

These injectors work like other HEUIs, except that the plunger incorporates a radial groove that receives fuel through six bleed ports drilled in the face of the plunger. As the piston moves downward, the groove aligns with a spill port in the barrel, shunting pressure. The output-side check ball seats and injection stops. Further piston movement masks the port and injection resumes.