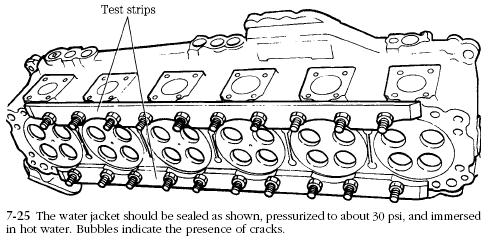

Figure 7-25 illustrates a Detroit Diesel cylinder head, partially dressed out for pressure testing. At this point, most shops would introduce high-pressure water into the jacket and look for leaks, which might take the form of barely perceptible seepage. Detroit Diesel suggests that air be used as the working fluid. Their approach calls for pressurizing the head to 30 psi and immersing the casting in hot (200 F) water for 30 minutes. Leaks register as bubbles.