System Operation Description:

Use this procedure under the following situation:

The “Two Speed Axle Switch” is suspected of incorrect operation.

Two Speed Axle Switch

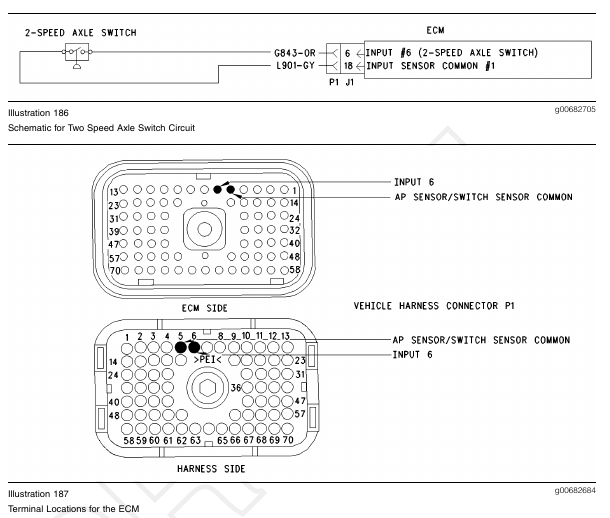

If a two-speed axle is used, the change in gear ratios alters the calibration of the vehicle speed signal. When the Two-Speed Axle Switch is in the ON position, the ECM will automatically adjust the vehicle speed calibration. This will ensure that the ECM driven speedometer and the stored information in the ECM correctly reflect the actual vehicle speed. In order for this feature to function properly, the “Low Speed Range Axle Ratio” and “High Speed Range Axle Ratio” parameters must be programmed. If the “Two Speed Axle Switch” parameter is programmed to “None” (default), this feature is not used. If the “Two Speed Axle Switch” parameter is programmed to J1/P1:6, the feature is available and the switch circuit should be connected to terminal 6 of the J1/P1 ECM connector. The switch can also be connected through the J1939 data link.

Note: The wiring for your particular application may be slightly different. The sensor common circuits are used interchangeably by the OEM of the vehicle.

The following circuits are common within the ECM:

• The “Input Sensor Common 1” is terminal 18.

• The “Input Sensor Common 2” is terminal 3.

• The “AP Sensor/Switch Sensor Common” is terminal 5.

Test Step 1. Check the Status of the “Two Speed Axle Switch”

A. Connect the electronic service tool to the data link connector.

B. Turn the key switch to the ON position.

C. Monitor the status for the “Two Speed Axle Switch” while the switch is operated in the ON and OFF positions.

D. If the “Two Speed Axle Switch” status indicates “Not Installed”, then the “Two Speed Axle Switch” parameter has not been programmed.

Expected Result:

The status screen should indicate “ON” if the switch is turned on. The status screen should indicate “OFF” if the switch is off.

Results:

• OK – The switch is operating normally. Continue troubleshooting if the original condition is not resolved. STOP.

• Not OK – The ECM is not reading the “Switch Status” change. Proceed to Test Step 2.

Test Step 2. Determine the Configuration of the Switch

A. Determine if the wiring for the switch is wired directly to the ECM or through the J1939 data link.

B. Verify that the “Two-Speed Axle Switch” parameter is programmed to reflect the proper wiring.

Expected Result:

The switch is wired directly to the ECM.

Results:

• OK – The switch is wired directly to the ECM.

Repair: Verify that the “Two-Speed Axle Switch” parameter is programmed to “J1/P1:6”.

Proceed to Test Step 3.

• Not OK – The switch is wired through the J1939 data link.

Repair: Verify that the “Two-Speed Axle Switch” parameter is programmed to “J1939 – Body Controller”, “J1939 – Cab Controller”, or “J1939 – Instrument Cluster”.

STOP.

Test Step 3. Check the Electrical Connectors and the Wiring

A. Thoroughly inspect the J1/P1 ECM connector, the connectors, and the firewall bulkhead connectors. Refer to Troubleshooting, “Electrical Connectors – Inspect” for details.

B. Perform a 45 N (10 lb) pull test on each of the wires in the ECM connector that are associated with the two speed axle switch circuit:

• terminal 6

• terminal 5

C. Check the ECM connector (allen head screw) for the proper torque of 6.0 N·m (55 lb in).

D. Check the harness and the wiring for abrasion and pinch points from the battery to the ECM.

Then, check from the key switch to the ECM.

Refer to Illustration 187 for terminal locations for the ECM.

Test Step 4. Check the Switch Circuit for the ECM.

A. Turn the key switch to the OFF position.

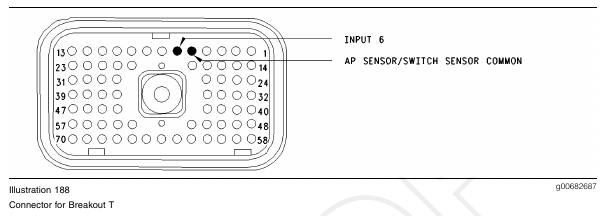

B. Install a 140-2266 Cable (Seventy-Pin Breakout) between the J1 and P1 ECM connector.

C. Fabricate a jumper wire 100 mm (4 inch) long.

Crimp a Deutsch pin to each end of the wire.

D. Insert the jumper wire into terminal 6 of the breakout T. Connect the other end of the jumper wire to terminal 5 (AP Sensor/Switch Common) of the breakout T.

E. Connect the electronic service tool to the data link connector.

F. Turn the key switch to the ON position.

G. Alternately remove the jumper wire and then insert the jumper wire from terminal 5. At the same time, monitor the status screen on the electronic service tool.

Expected Result:

The switch status changes to “ON” with the jumper wire in place. The switch status changes to “OFF” when the jumper wire is removed.

Results:

• OK – The ECM is functioning properly at this time.

Repair: Remove the breakout T and reconnect the J1 and P1 ECM connectors.

Proceed to Test Step 5.

• Not OK – The ECM is not functioning properly.

Repair: Perform the following repair:

1. Temporarily connect a test ECM.

2. Remove the breakout T and reconnect the J1 and P1 ECM connectors.

3. If the problem is resolved with the test ECM, reconnect the suspect ECM.

4. If the problem returns with the suspect ECM, replace the ECM.

5. Verify that the repair eliminates the problem.

STOP.

Test Step 5. Insert a Jumper Wire at the Switch

A. Turn the key switch to the OFF position.

B. Fabricate a jumper wire 100 mm (4 inch) long.

Crimp a Deutsch pin to both ends of the wire.

C. Locate the switch for the Two-Speed Axle.

Insert the jumper wire between the two switch terminals.

D. Turn the key switch to the ON position.

E. Alternately remove the jumper wire and then insert the jumper wire at the switch terminals. At the same time, watch the status screen on the electronic service tool.

Expected Result:

The switch status changes to “ON” with the jumper wire in place. The switch status changes to “OFF” when the jumper wire is removed.

Results:

• OK – Replace the switch. Verify that the repair solves the problem. STOP.

• Not OK – There is a problem in the wire harness between the switch for the two-speed axle and the ECM. Proceed to Test Step 6.

Test Step 6. Insert a Jumper Wire at the Bulkhead Connector

A. Turn the key switch to the OFF position.

B. Fabricate a jumper wire 100 mm (4 inch) long.

Crimp a Deutsch pin to both ends of the wire.

C. Locate the two speed axle switch socket in the engine side of the ECM bulkhead connector.

D. Insert the wire jumper pin between the switch socket and the sensor common connection.

Install the jumper wire on the engine side of the ECM bulkhead connector.

E. Turn the key switch to the ON position.

F. Alternately connect and then disconnect the jumper wire. At the same time, monitor the status screen on the electronic service tool.

Expected Result:

The switch status changes from “ON” with the jumper wire in place. The switch status changes to “OFF” when the jumper wire is removed.

Results:

• OK – The problem is in the vehicle wiring between the bulkhead connector and the switch.

Inspect the vehicle wiring and then repair the vehicle wiring. Otherwise, send the vehicle to the OEM dealer for repair. Verify that the original condition is resolved. STOP.

• Not OK – The problem is in the vehicle wiring between the bulkhead connector and the ECM.

Inspect the vehicle wiring and then repair the vehicle wiring. Otherwise, send the vehicle to the OEM dealer for repair. Verify that the original condition is resolved. STOP.